If you have invested a lot of your money in an air compressor, you should know how to maintain it and keep running it well. That’s where you would need an air compressor oil so that your air compressor runs as you want it whenever you need it. It works just like oil in your car and needs to be changed regularly. But what does the air compressor exactly do that we have to change it frequently? Let’s find out!

Importance of changing Air Compressor Oil

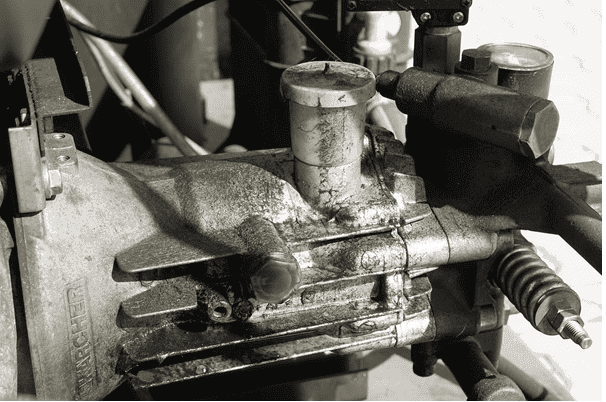

Air compressor oil acts as a lubricant for the ball bearings and reduces the carbon deposits inside a compressor. It cools down the moving parts and tightens the seal in certain areas.

It helps in removing all the impurities and keep the device’s components running smoothly. If you change the oil regularly, you can prevent overheating in your air compressor and reduce the overall wear and tear of your motor.

Without lubricating your compressor oil, the moving components of the compressor will decay at a faster rate and break away at any time. And you need to do the lubrication regularly because oil loses its viscosity gains and thickens with time, being unable to distribute evenly.

At Bestfordriver website has a lot of best synthetic compressor oil which we can recommend, it has worked great so far, and users love it. Thus, air compressor oil has a significant role in defining the life of an air compressor.

When should you change Air Compressor Oil?

Now you know how important it is to change the compressor oil for the effective running of the machine. But the next big thing you need to worry about is what should be the periodicity to change your air compressor oil.

The regularity of changing the oil entirely depends on the type of air compressor you are using. Majorly, there are two types of air compressors; rotary screw and reciprocating compressor.

If you have a rotary screw compressor, it will run continuously without any on and off switch. Large industries often use this type of compressor.

The ideal recommendation of changing the oil in this compressor is 7000-8000 machine hours usage. But if your manufacturer has provided different guidance based on your compressor, you can follow that.

Another type of compressor, the reciprocating compressor uses pistons driven by a crankshaft to compress the gas. You can observe metal-to-metal contact in these machines; therefore, lubrication is necessary to prevent such incidents.

And thus, we recommend lubricating your compressor every 500 hours of usage or three months whichever is earlier. But, as we said, your manufacturer may have a different type of recommendation for the frequency of changing compressor oil, so keep that in mind.

Conclusion

Air compressor oil acts as blood in your body and ensures movement in your limbs. If the oil is not running in some parts of your machine, it might get jammed and may not function properly. So, keep a check on the oil in your compressor. And read all the manuals carefully before lubricating your machine yourself.

Source: naijatechguide.com